At Archway Tensile, we take pride in being a leading manufacturer and architect specializing in the innovative design and construction of breathtakingly tensile structures throughout India. With a strong commitment to quality, creativity, and customer satisfaction, we bring your visions to life with our expertise in tensile structure architecture.

What is a Tensile Structure?

Tensile structures are architectural marvels that utilize tensioned fabric membranes or sheets to create stunning, lightweight structures that span large distances without the need for internal support columns. These structures are known for their versatility, durability, and aesthetic appeal, making them ideal for a wide range of applications, including commercial buildings, event spaces, walkways, canopies, and more.

Why Choose Archway Tensile as Your Tensile Structure Architect in India?

As a trusted name in the industry, Archway Tensile combines design ingenuity with technical expertise to deliver exceptional tensile structure solutions tailored to your specific needs. Our team of experienced architects, engineers, and craftsmen work closely with clients to design, fabricate, and install custom tensile structures that exceed expectations.

Tensile Structure Architecture at Its Finest

Our portfolio showcases a diverse range of projects, including iconic tensile structure buildings, elegant tensile structure canopies, striking entrance archways, and functional outdoor shelters. Each project is a testament to our commitment to innovation, sustainability, and excellence in tensile structure architecture.

Transforming Spaces with Tensile Structures in India

India's rich architectural heritage and vibrant culture provide the perfect canvas for the integration of modern tensile structures. From bustling urban landscapes to serene natural settings, our designs seamlessly blend with their surroundings, creating visually striking focal points that enhance the built environment.

Experience the Difference with Archway Tensile

When you choose Archway Tensile as your partner in tensile structure design and construction, you can expect a seamless process from concept to completion. Our team leverages cutting-edge technology, premium materials, and precise craftsmanship to deliver superior results that stand the test of time.

Whether you are looking to add a touch of elegance to your commercial property, create a unique event space, or enhance the functionality of outdoor areas, Archway Tensile has the expertise and creativity to bring your vision to life.

Tensile structures in India come in a variety of shapes and designs, each offering unique aesthetics, functionality, and architectural appeal. From iconic landmarks to practical shelters, tensile structures have become synonymous with innovation and creativity in the Indian architectural landscape. Here are some of the most common types of tensile structures shapes and designs found in India:

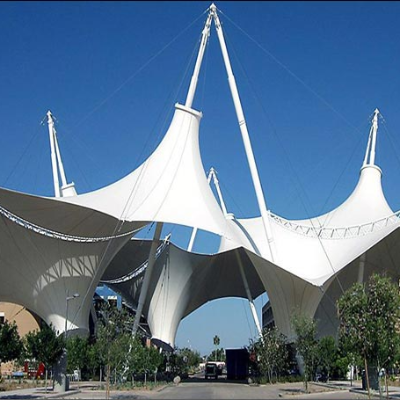

1. Cone Tensile Structures: Cone-shaped tensile structures are characterized by their elegant, tapered form that rises to a point. These structures are often used as entrance features, canopies, or decorative elements in public spaces, parks, and commercial complexes. Cone structures add a touch of sophistication and visual interest to any environment.

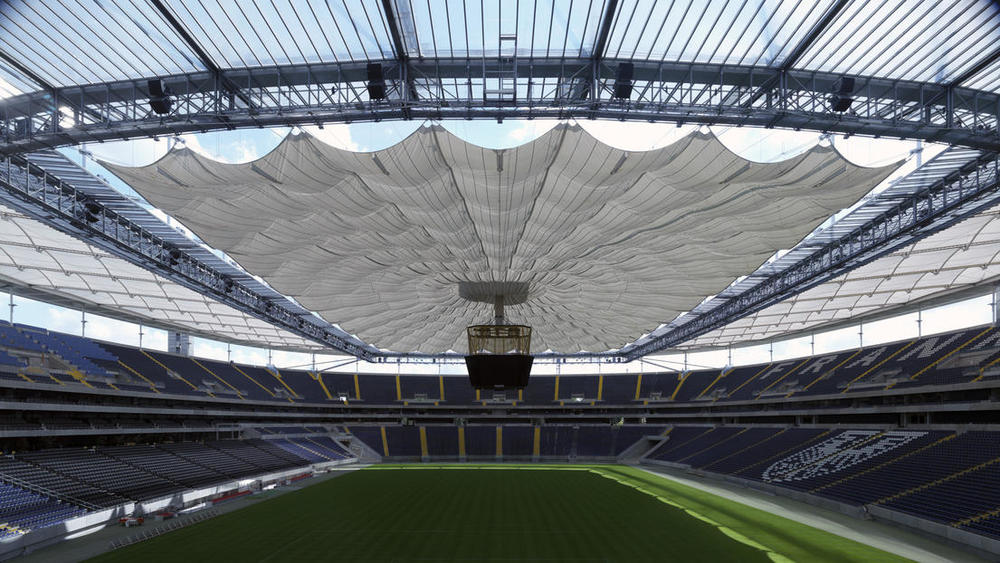

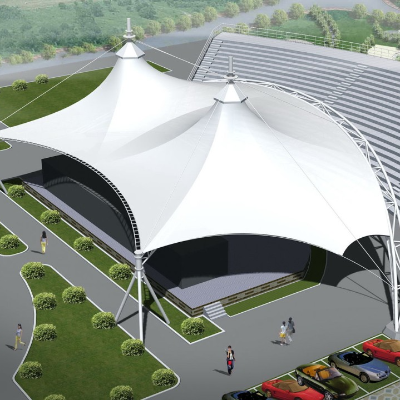

2. Dome Tensile Structures: Dome-shaped tensile structures are iconic for their curved, hemispherical design that offers ample interior space and a striking exterior profile. These structures are popular for event venues, exhibition spaces, and religious buildings due to their grandeur and versatility. Dome structures in India often showcase intricate fabric patterns and lighting effects to create a mesmerizing atmosphere.

3. Sail Tensile Structures: Sail-shaped tensile structures mimic the graceful curves of billowing sails on a ship, creating a sense of movement and fluidity in the built environment. These structures are commonly used as shade sails, awnings, and outdoor seating covers in parks, playgrounds, and residential complexes. Sail structures in India come in a range of sizes and configurations, offering both practical sun protection and artistic flair.

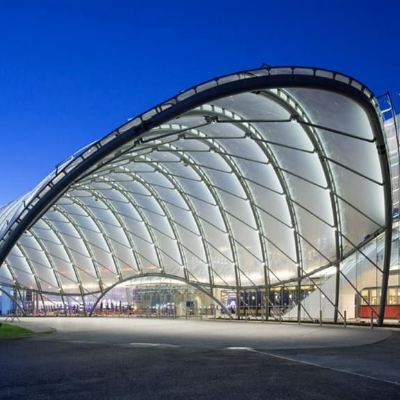

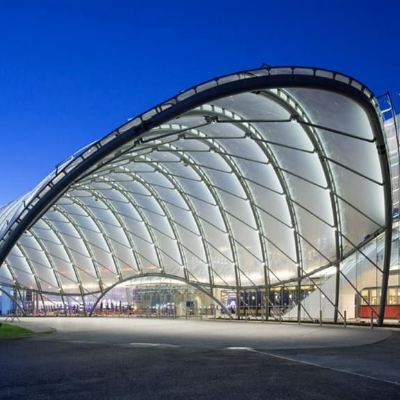

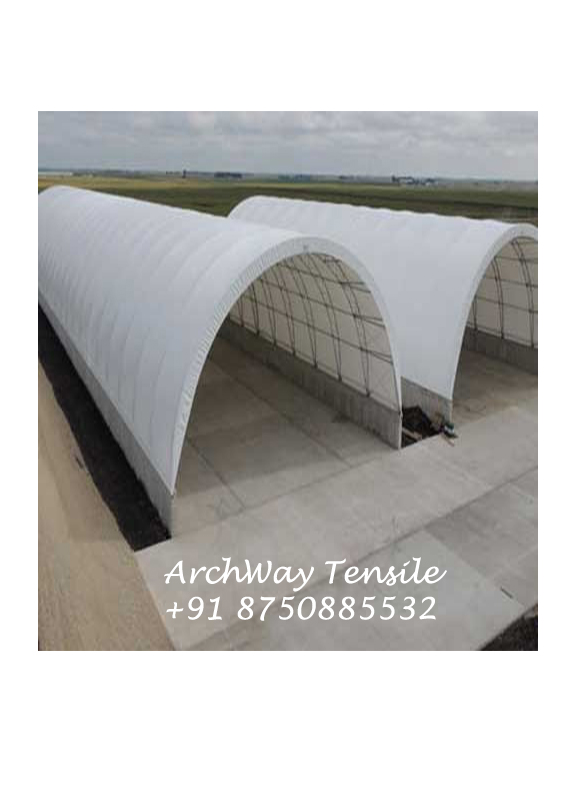

4. Archway Tensile Structures: Arch-shaped tensile structures are known for their sweeping curves that form elegant entryways, walkways, or focal points in public spaces, gardens, and event venues. These structures exude a sense of grandeur and sophistication, drawing attention and guiding visitors through the space. Archway structures in India often feature intricate fabric designs and lighting accents to create a captivating visual impact.

5. Cantilever Tensile Structures: Cantilevered tensile structures are characterized by their extended horizontal projections that appear to defy gravity and create a sense of weightlessness. These structures are ideal for creating covered walkways, outdoor seating areas, and building facades that command attention and provide shelter. Cantilever structures in India showcase innovative engineering and design techniques to achieve impressive spans and architectural feats.

6. Conical Tensile Structures: Conical tensile structures feature a conical shape that tapers from a wide base to a pointed top, creating a visually striking silhouette that stands out in any setting. These structures are commonly used as event pavilions, exhibition booths, and temporary shelters for outdoor events and festivals. Conical structures in India offer a blend of functionality and aesthetics, making them popular choices for a range of applications.

The diverse range of tensile structure shapes and designs in India reflects the country's rich architectural heritage, creativity, and commitment to innovation. Whether enhancing urban landscapes, creating functional spaces, or celebrating cultural events, tensile structures continue to captivate and inspire with their beauty and ingenuity.

The engineering behind tensile structures is a fascinating blend of art, science, and innovation that allows for the creation of lightweight, durable, and visually striking architectural marvels. Tensile structures rely on the principles of tension and compression to achieve their unique shapes and designs, offering a wide range of applications in various industries, including architecture, construction, and design. Here is an overview of the key engineering aspects behind tensile structures:

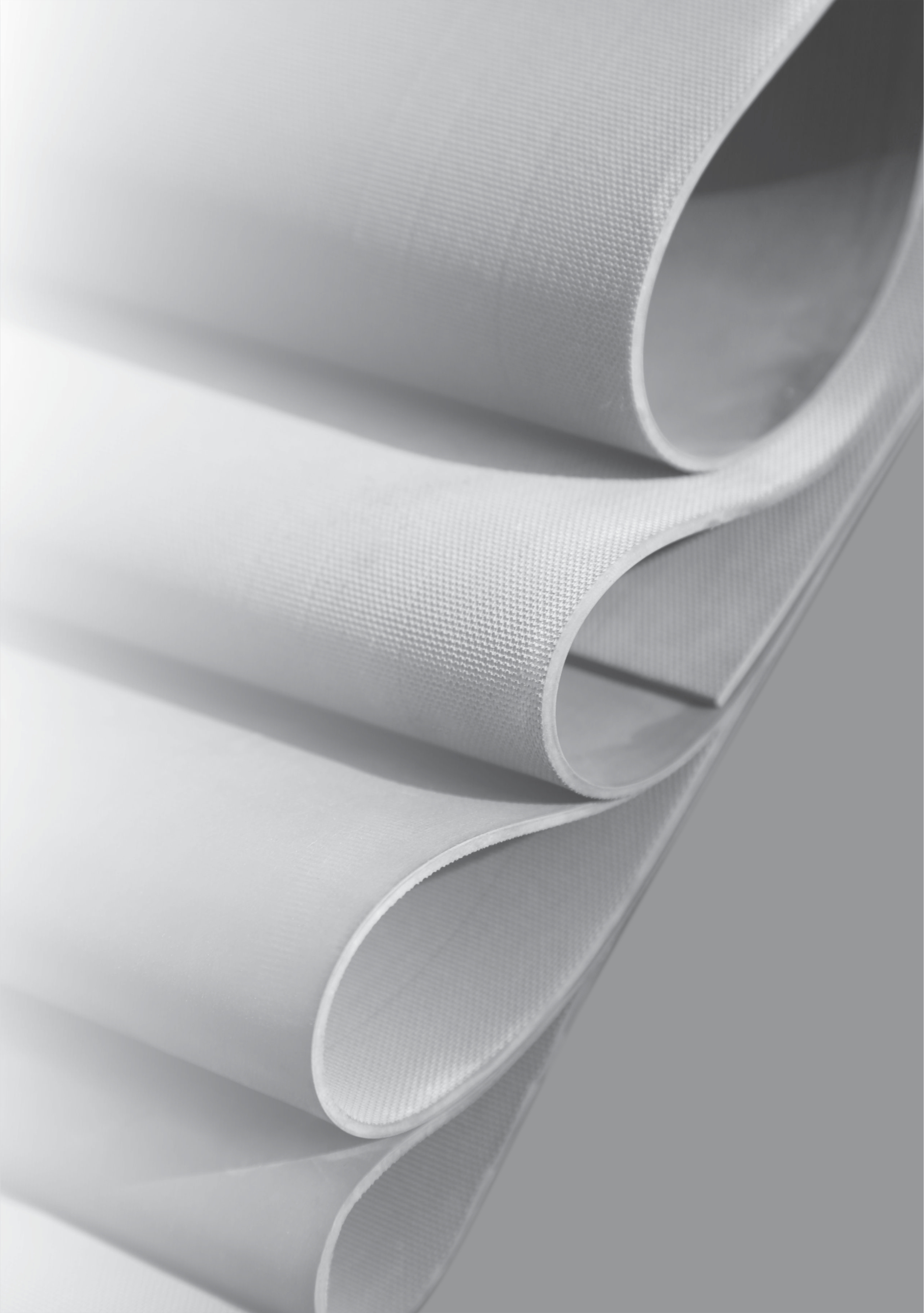

1. Tensioned Fabric Membranes: At the heart of every tensile structure is a tensioned fabric membrane that serves as the primary load-bearing element. These membranes are typically made of high-strength materials such as PVC-coated polyester, PTFE-coated fiberglass, or ETFE film, known for their durability, flexibility, and weather resistance. The fabric is tensioned between support points, creating a stable surface that can span large distances without the need for internal columns or walls.

2. Structural Analysis and Form Finding: Engineers use advanced computational tools and software to analyze the structural behavior of tensile structures and optimize their shape and form. Form-finding techniques help determine the most efficient geometry for the fabric membrane based on factors such as wind loads, snow loads, and material properties. By simulating different scenarios and stress conditions, engineers can ensure that the structure meets safety standards and performance requirements.

3. Support Systems: Tensile structures rely on a network of support systems to distribute loads and ensure structural stability. These systems include steel or aluminum frames, cables, tension rods, and anchor points that work together to maintain the integrity of the fabric membrane under various forces. Engineers carefully design the support systems to withstand dynamic loads such as wind, snow, and seismic activity while allowing for movement and flexibility to accommodate environmental changes.

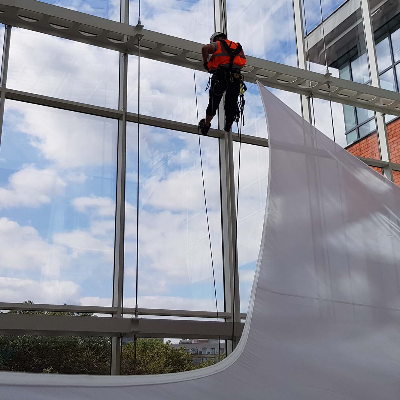

4. Fabrication and Installation: Fabrication of tensile structures involves precise cutting, welding, and sewing of the fabric membrane to create custom shapes and patterns. Skilled craftsmen work in collaboration with engineers to ensure the accurate assembly of components and the seamless integration of structural elements. Installation of tensile structures requires careful planning, coordination, and expertise to achieve proper tensioning, alignment, and anchoring for optimal performance and longevity.

5. Material Selection and Durability: The selection of materials plays a crucial role in the engineering of tensile structures, as different fabrics and coatings offer varying levels of strength, UV resistance, flame retardancy, and translucency. Engineers consider factors such as climate conditions, maintenance requirements, and aesthetic preferences when choosing materials to ensure the longevity and performance of the structure. Proper material selection contributes to the durability, sustainability, and visual appeal of tensile structures over time.

The engineering behind tensile structures represents a harmonious balance of creativity, functionality, and technical expertise. By leveraging advanced engineering principles, innovative design techniques, and high-quality materials, engineers can create awe-inspiring structures that push the boundaries of architectural possibilities and enrich the built environment with beauty and innovation.

Tensile structures offer several advantages that make them a popular choice for architectural and construction projects:

1. Aesthetic Appeal: Tensile structures provide unique and visually striking architectural designs. Their ability to create fluid shapes and curves allows for the creation of modern and aesthetically pleasing buildings, canopies, and shelters.

2. Natural Light and Ventilation: Tensile structures can be designed to allow natural light to filter through, creating well-lit and airy spaces. This feature not only reduces the need for artificial lighting during the day but also enhances the overall comfort and well-being of occupants.

3. Versatility in Design: Tensile structures offer a high degree of design flexibility. They can be customized to fit various sizes and shapes, making them suitable for a wide range of applications such as stadiums, exhibition halls, atriums, car parks, and more.

4. Cost-Effectiveness: Tensile structures require fewer materials compared to traditional buildings, resulting in lower construction costs. This cost efficiency makes them an attractive option for projects with budget constraints.

5. Durability: Tensile structures are known for their durability and longevity. They are designed to withstand various weather conditions, including heavy rain, wind, and snow, making them a reliable choice for both temporary and permanent structures.

6. Quick Installation: Tensile structures can be installed relatively quickly compared to traditional construction methods. This rapid installation time can help reduce project timelines, allowing for faster completion of projects.

7. Sustainability: Tensile structures are considered environmentally friendly as they use fewer materials during construction. Additionally, they can be made from recyclable materials, further reducing their environmental impact.

8. Energy Efficiency: Tensile structures can incorporate energy-efficient features such as solar panels and rainwater harvesting systems. These sustainable elements help reduce energy consumption and promote environmental conservation.

9. Low Maintenance: Tensile structures require minimal maintenance compared to traditional buildings. Routine inspections and cleaning are usually sufficient to keep the structure in good condition, resulting in long-term cost savings.

The advantages of tensile structures, including their aesthetic appeal, versatility, cost-effectiveness, durability, sustainability, and energy efficiency, make them a popular choice for a wide range of architectural and construction projects.

Car Parking Tensile Structure

Car Parking Tensile Structure Conical Tensile Structure

Conical Tensile Structure Gazebo Tensile Structure

Gazebo Tensile Structure Retractable Tensile Roof

Retractable Tensile Roof Tensile Architecture

Tensile Architecture Tensile Canopy

Tensile Canopy Tensile Canopy Structure

Tensile Canopy Structure Tensile Car Parking

Tensile Car Parking Tensile Car Parking Manufacturer

Tensile Car Parking Manufacturer Tensile Car Parking Shed

Tensile Car Parking Shed Tensile Cloth Shed

Tensile Cloth Shed Tensile Fabric

Tensile Fabric Tensile Fabric Canopy

Tensile Fabric Canopy Tensile Fabric Manufacturer

Tensile Fabric Manufacturer Tensile Fabric Roof

Tensile Fabric Roof  Tensile Fabric Shed

Tensile Fabric Shed Tensile Gazebo

Tensile Gazebo Tensile Membrane Fabric

Tensile Membrane Fabric Tensile Membrane Structure

Tensile Membrane Structure Tensile Parking Shed

Tensile Parking Shed Tensile Roof

Tensile Roof Tensile Roofing

Tensile Roofing Tensile Shade

Tensile Shade Tensile Shed

Tensile Shed Tensile Sheet Roofing

Tensile Sheet Roofing Tensile Structure Car Parking

Tensile Structure Car Parking Tensile Structure Manufacturer

Tensile Structure Manufacturer Tensile Structures in India

Tensile Structures in India Tensile Umbrella

Tensile Umbrella Auditorium Tensile Structure

Auditorium Tensile Structure Entrance Tensile Structure

Entrance Tensile Structure Stadium Tensile Structure

Stadium Tensile Structure Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Tensile Car Parking Shade

Tensile Car Parking Shade Tensile food Court Structure

Tensile food Court Structure Tensile Lightweight Structure

Tensile Lightweight Structure Tensile Roof Structure

Tensile Roof Structure Walkway Covering Structure

Walkway Covering Structure Arch Supported Tensile Structure

Arch Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Canopy Architecture

Canopy Architecture Canopy Tensile Structure

Canopy Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Car Parking Canopy Structure

Car Parking Canopy Structure Car Parking Structure

Car Parking Structure Car Parking Tensile Shed

Car Parking Tensile Shed Car Parking Tensile Structure Manufacturers

Car Parking Tensile Structure Manufacturers Dome Tensile Structure

Dome Tensile Structure Fabric Structure

Fabric Structure Fabric Tensile Structure

Fabric Tensile Structure Ferrari Fabric Roof

Ferrari Fabric Roof Ferrari Tensile Fabric

Ferrari Tensile Fabric Ferrari Tensile Structure

Ferrari Tensile Structure Hyper Tensile Structure

Hyper Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Linear Tensile Structures

Linear Tensile Structures Mast Supported Tensile Structure

Mast Supported Tensile Structure Mehler Tensile Fabric

Mehler Tensile Fabric Membrane Tensile Structure

Membrane Tensile Structure Modular Tensile Structure

Modular Tensile Structure PTFE Tensile Fabric

PTFE Tensile Fabric PVC Coated Tensile Fabric

PVC Coated Tensile Fabric PVC Tensile Fabric

PVC Tensile Fabric Tensile Car Parking Structure

Tensile Car Parking Structure Tensile Car Porch

Tensile Car Porch Tensile Car Shed

Tensile Car Shed Tensile Ceiling

Tensile Ceiling Tensile Company

Tensile Company Tensile Cone Structure

Tensile Cone Structure Tensile Covering

Tensile Covering Tensile Dome Structure

Tensile Dome Structure Tensile Fabric Car Shed

Tensile Fabric Car Shed Tensile Fabric Clothing

Tensile Fabric Clothing Tensile Fabric Company

Tensile Fabric Company Tensile Fabric Covering

Tensile Fabric Covering Tensile Fabric Facade

Tensile Fabric Facade Tensile Fabric Gazebo

Tensile Fabric Gazebo Tensile Fabric India

Tensile Fabric India Tensile Fabric Installation

Tensile Fabric Installation Tensile Fabric Roof Installation

Tensile Fabric Roof Installation Tensile Fabric Roofing

Tensile Fabric Roofing Tensile Fabric Roofs

Tensile Fabric Roofs Tensile Fabric Shade

Tensile Fabric Shade Tensile Fabric Shade Structure

Tensile Fabric Shade Structure Tensile Fabric Sheet

Tensile Fabric Sheet Tensile Fabric Structure Manufacturer

Tensile Fabric Structure Manufacturer Tensile Fabric Structure

Tensile Fabric Structure Tensile Fabric Supplier

Tensile Fabric Supplier Tensile Fabrication

Tensile Fabrication Tensile Manufacturer

Tensile Manufacturer Tensile Membrane

Tensile Membrane Tensile Membrane Roof

Tensile Membrane Roof Tensile Parking

Tensile Parking Tensile Parking Structure

Tensile Parking Structure Tensile Pergola

Tensile Pergola Tensile Roof Fabric

Tensile Roof Fabric Tensile Roof Installation

Tensile Roof Installation Tensile Roofing Structure

Tensile Roofing Structure Tensile Shade Structure

Tensile Shade Structure Tensile Sheet Shed

Tensile Sheet Shed Tensile Steel Structure

Tensile Steel Structure Tensile Structure Canopy

Tensile Structure Canopy Tensile Structure Company

Tensile Structure Company Tensile Structure Fabric

Tensile Structure Fabric Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Restaurant

Tensile Structure for Restaurant Tensile Structure Installation

Tensile Structure Installation Tensile Structure Parking

Tensile Structure Parking Tensile Structure Roof

Tensile Structure Roof Tensile Structures Architecture

Tensile Structures Architecture Tensile Tent Structures

Tensile Tent Structures Tensile Umbrella Structures

Tensile Umbrella Structures Tensile Work

Tensile Work Tension Structure

Tension Structure Transparent Tensile Fabric

Transparent Tensile Fabric Umbrella Tensile Structure

Umbrella Tensile Structure Walkway Tensile Structure

Walkway Tensile Structure Waterproof Tensile Fabric

Waterproof Tensile Fabric Cafeteria Canopy Tensile Structure

Cafeteria Canopy Tensile Structure